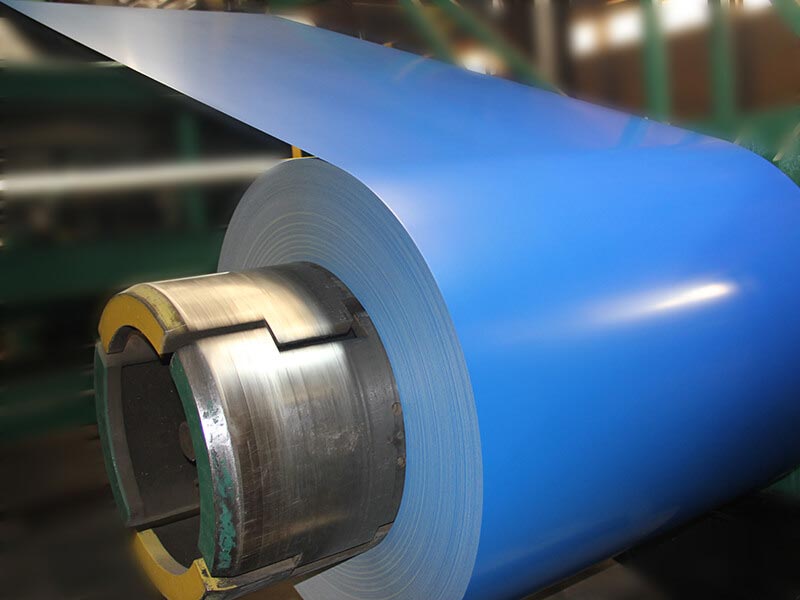

Prepainted Steel Coil

Prepainted Steel Coil is a type of steel coil that has been coated with a layer of protective zinc. This coating helps to prevent corrosion and extends the lifespan of the steel. Here are some of the product advantages and features:

1.Easy maintenance: Galvanized steel coils require minimal maintenance. The zinc coating helps to prevent the formation of rust, reducing the need for frequent painting or repairs. Regular cleaning is usually sufficient to keep the surface in good condition.

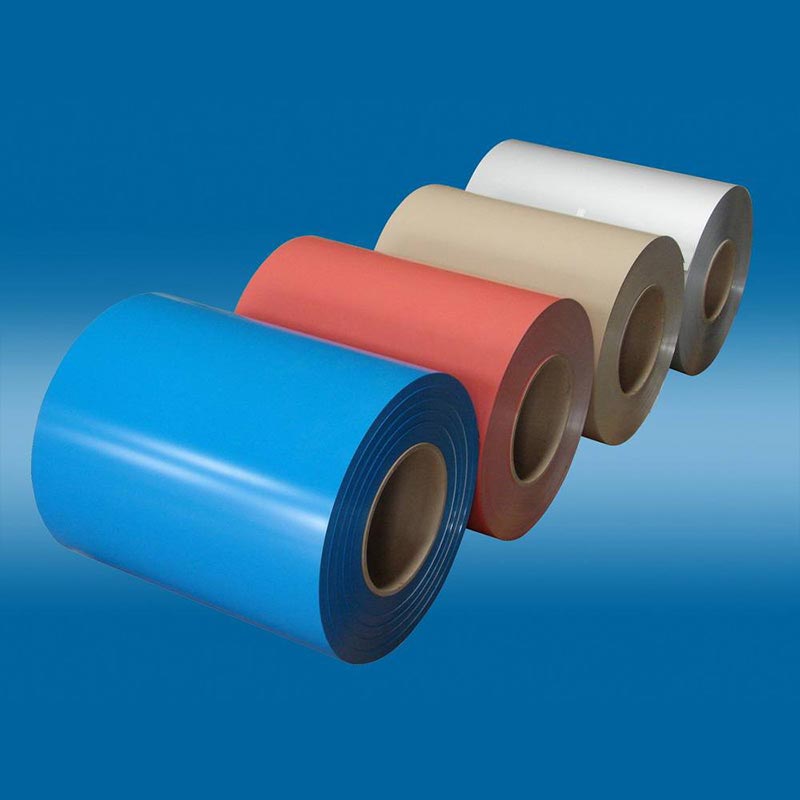

2.Customization: Galvanized steel coils can be produced in different sizes, thicknesses, and grades to meet specific requirements. This allows for customization based on the application and desired performance characteristics.

3.Cost-effective: Galvanized steel coils are a cost-effective option compared to other types of coated steel or non-coated steel. The initial investment may be slightly higher, but the long-term benefits and extended lifespan outweigh the additional cost.

4.Environmentally friendly: Galvanized steel is a sustainable and recyclable material. At the end of its lifespan, it can be recycled and used to produce new steel products, reducing the reliance on virgin materials and minimizing waste.

Overall, galvanized steel coils offer excellent corrosion resistance, durability, versatility, and cost-effectiveness. They are a reliable choice for various applications and can be customized to meet specific needs.

PRODUCT PARAMETERS

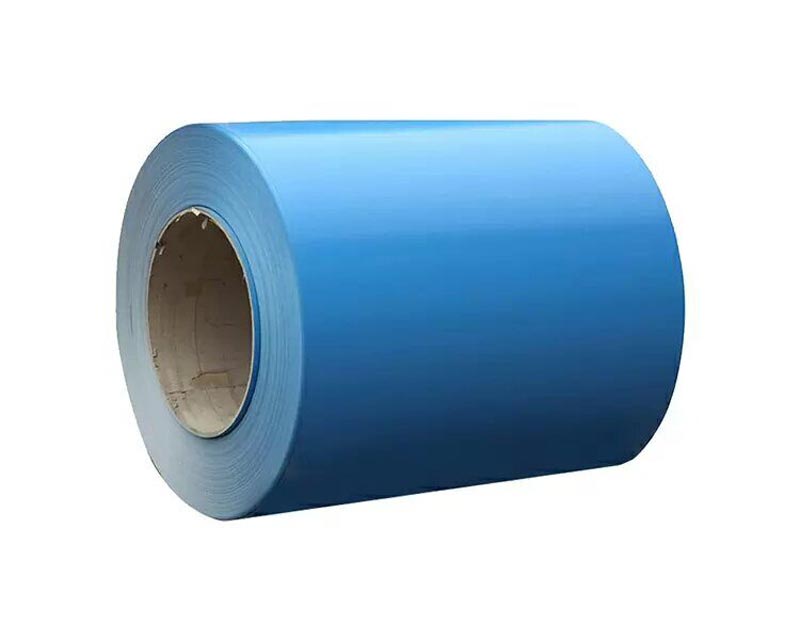

The prepainted metal sheet in coil is a product bought by way of subjecting a hot-dipped galvanized metal sheet, and galvalume metal sheet, or an aluminum sheet to a floor chemical remedy (coating), observed with the aid of baking and curing.

The whole thickness of the pre-panted galvanized metal coil is composed of the base metal – coating -primer – pinnacle paint – protecting layer thickness. The pinnacle paint thickness is 10-25μm, and the returned paint thickness is 5-20μm. The thinner the base metal thickness, the greater the rate of the ppgi metal coil, due to the fact the processing fee turns into higher.

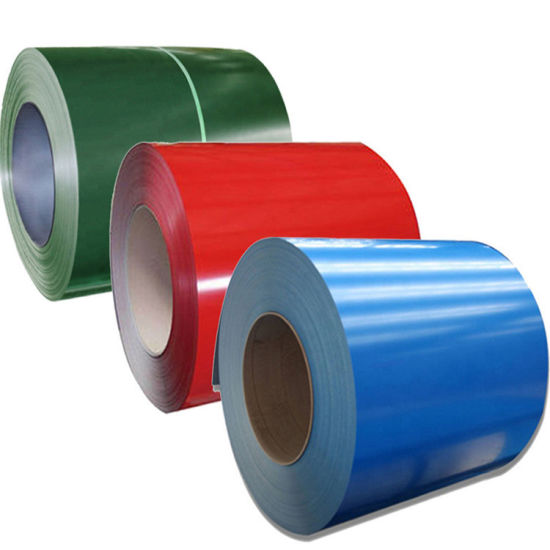

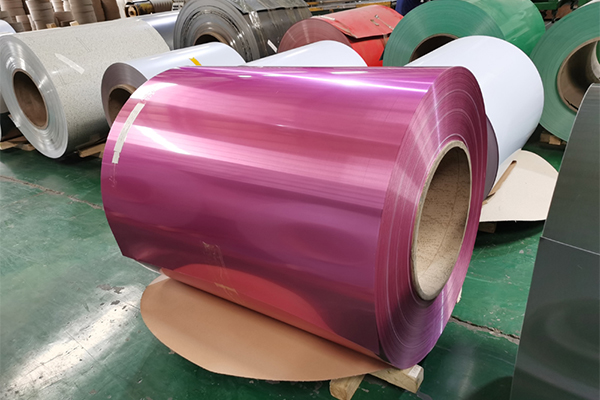

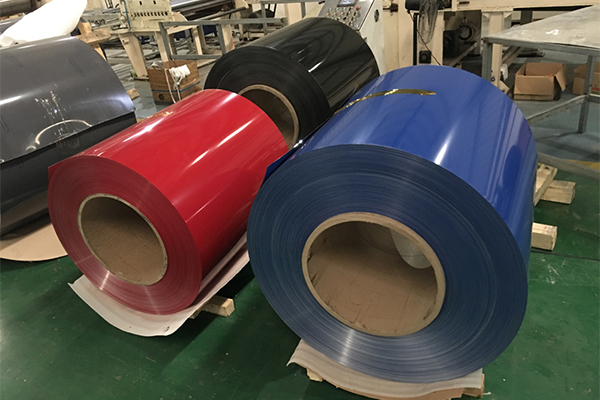

Usually, the paint coating fabric is polyester (PE) and the coloration of the again paint is white grey. The colour can be custom-made in accordance to the RAL shade card or consumer samples. Special patterns can be made, such as wooden grain, flower print, camouflage, brick.

PPGI is additionally recognized as prepainted galvanized metal coil and coloration covered metal coil, with a warm dip zinc covered metal sheet substrate. PPGL is additionally regarded as prepainted galvalume metal coil, with a galvalume metal sheet as a substrate.

PPGI Coil Production Process

PPGI Sheet Coating Layer

Unrolling – Stitching machine – Entrance loop – Pretreatment – Initial coating – Bake – Cool down – Fine coating – Bake – Embossed film – Export loop – Inspection station – Cut – Coiling

In the above process, if the cleaning degreasing process is not handled well, the adhesion of the primer of the color coated plate to the galvanized sheet is not good, and it is easy to cause the topcoat of the color coated steel coil to fall off during the press forming process.

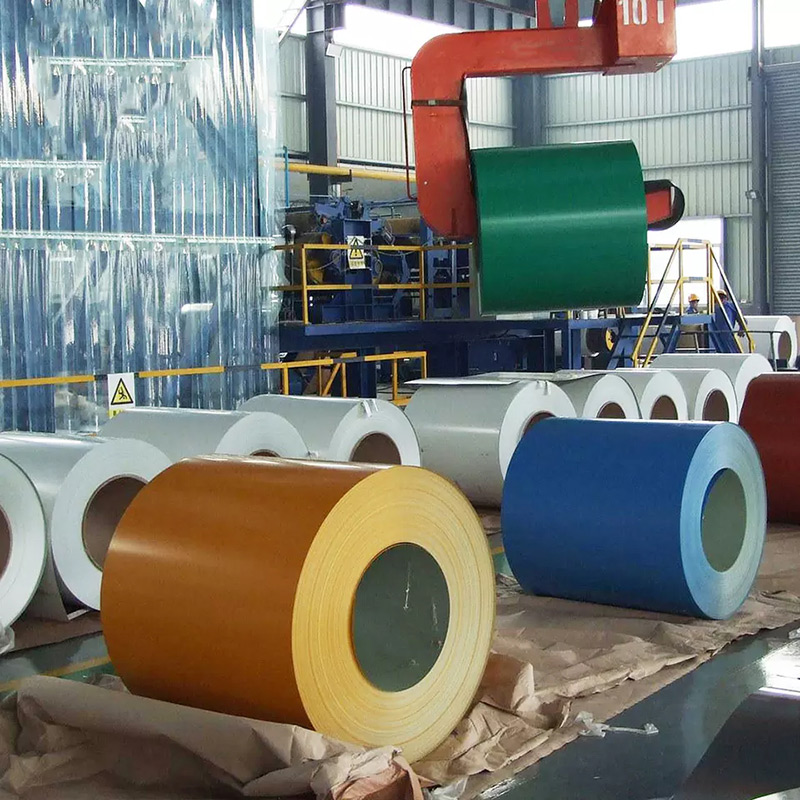

WAREHOUSE

Here are some of the product advantages and features:

1.Corrosion resistance: The zinc coating acts as a barrier between the steel and the environment, protecting it against rust and corrosion. This makes galvanized steel coils ideal for outdoor applications or in environments with high humidity or corrosive elements.

2.Durability: Galvanized steel coils are known for their durability and long-lasting performance. The zinc coating provides an extra layer of protection that helps to resist damage from scratches, impacts, and abrasions, making it suitable for heavy-duty applications.

3.Versatility: Galvanized steel coils can be used in a variety of applications across various industries. They are commonly used in construction for roofing, siding, and structural components. They are also used in automotive manufacturing, appliances, and electrical enclosures.

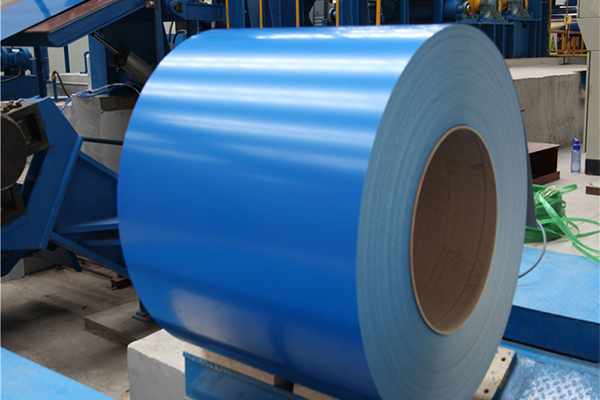

As a expert iron and metal manufacturing enterprise, our organization has a range of manufacturing lines. The month-to-month manufacturing ability of GI PPGL PPGI COIL is extra than 30000 tons, which can meet your demand for excessive excellent products. If it really is no longer adequate for you, we have additionally signed annual income contracts with quite a few massive metal mills in China. We have an authentic manufacturing unit cloth record for all our steel. No remember how huge your order is, we can meet your requirement.

We have handed ISO 9001 global first-class machine certification.We have export to greater than eighty nations and have loved a excessive reputation.

PRODUCT PACKAGING

Standard Seaworthy Export Packing:

3 layers of packing, interior is kraft paper, water plastic movie is in the center and backyard GI metal sheet to be included by way of metal strips with lock.

1. Export seaworthy packing: a water proof paper + an inhibitor movie + a metal sheet cowl with metal part protectors and ample metal straps

2. Packaging detail:as customer's requirements.

Related News

Submitted successfully

We will contact you as soon as possible